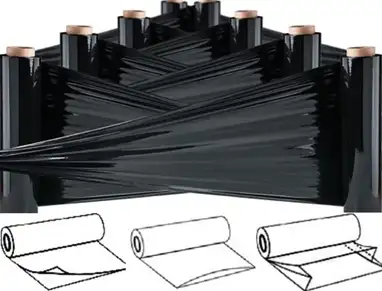

TUBES/HOSE LDPE/MDPE/PP

We produce flame-retardant film and hose in accordance with DIN 4102 and EN 13501-1 in fire protection classes B1 and B2.

We produce flame-retardant film and hose in accordance with DIN 4102 and EN 13501-1 in fire protection classes B1 and B2.

The film has a whitish yellow color. It can also be equipped with antistatic agents. A different coloring can be done according to your wishes.

Do you have a need or do you need further information?

Contact us

Tubular film is also known as film tubing, packaging tubing, tubular bag film, continuous tubing, tubular film, and blown film. During extrusion, the polyethylene (PE) granulate is melted and inflated into a film tubing using pressure and air. The tubing is rewound onto rolls or cut to size according to customer requirements. Our semi-tubular film allows you to easily package the packaged goods thanks to its side opening. We also manufacture other tubing variants according to your requirements, such as gathered tubing, side-gusseted tubing, side-gusseted tubing cuts, and side-gusseted shrink tubing.

As additives, we can treat the tubing with antistatic, anti-blocking, anti-fog, electrically conductive, food-safe, flame-retardant, or UV-resistant additives. Upon request, we can dye your tubing in all possible colors.

Of course, we also supply tubing in "food-safe" quality.

The surface is either lubricious, needle-punched, or non-slip. All colors are available: transparent, opaque, or translucent. Upon request, we can also offer tubing with full-surface needling. This needling ensures the escape of air during packaging.

We process polyolefins such as high-pressure (LDPE), medium-pressure (MDPE), blended films of the aforementioned materials, as well as polypropylene (PP), and various composite films. All raw materials and masterbatches we use are certified. A REACH declaration of conformity is available for each raw material type. Each delivered batch has a batch certificate. These are managed and monitored within our quality management system. Depending on requirements and applications, we also have FDA approval.

We provide expert advice on solving your packaging requirements, thus contributing to highly efficient and therefore cost-optimized packaging processes.

An in-house quality assurance system ensures that all products can be tested and certified upon request.

We have been producing top quality in Rheinberg since 1951. Short delivery times are guaranteed. Smaller quantities are also possible. You will receive your quote immediately. Buy our tubing products directly from the manufacturer.

Our hose products are environmentally friendly because they are 100% recyclable, biodegradable, and groundwater-neutral. Using various material processes, the used plastic packaging can either be directly remelted into new products or processed into regranulate. Our in-house regenerated material (rLDPE) is pure and a cost-effective alternative to virgin material, as well as a high-quality raw material for films and garbage bags.

Shirring hose/tube

Used for packaging machines for powder filling. A certain length of flat tube is gathered and tied onto a cardboard sleeve. Diameter and hose length depend on the machine used.

More information about foils and films can be found on our FAQ pages.

Or use our keyword search. Here you can search for any term.