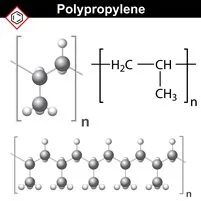

What is Polypropylene (PP) ?

Polypropylene is a thermoplastic produced by the chain polymerization of propen. It belongs to the polyolefin group, is nonpolar, and semi-crystalline. Its low density ranges from 0.895 g/cm³ to 0.920 g/cm³. It is produced by the polymerization of propylene and is widely used in many areas of everyday life. The upper service temperature is 100°C to 110°C. The melting point is 160°C.

PP is chemically relatively similar to PE, but significantly harder, stronger, and has a higher thermal resistance. Polypropylene has greater stiffness, hardness, and strength than polyethylene, but these are lower than those of other plastics such as polyamide. It is also resistant to moisture, oils, solvents, and many chemicals. Polypropylene is also resistant to fracture and fatigue, making it a versatile material. Due to its low surface energy, it is very difficult to bond and print. Polypropylene is odorless and skin-friendly. It is suitable for applications in the food and pharmaceutical industries. It is physiologically safe.

Polypropylene is generally highly recyclable. Polypropylene can be identified by its recycling code 05. This means that polypropylene can be considered a sustainable plastic.

Recycling polypropylene in the form of blends, however, is more difficult. Recyclability is limited by the addition of reinforcements or fillers and is only possible through special processing.

Polypropylene is a widely used material used in a wide variety of applications due to its versatility and excellent properties.

Other properties:

Water Vapor Permeability PE

Oxygen Permeability PE

Material Restistance LDPE

With the help of our online foil calculator you can determine the weight, the foil area, the roll diameter and the foil thickness of your desired product yourself.

You can find an overview of our currently available stock here.

We currently have the following products in stock and can be ordered:

| Mat.AL | ArticleL | TEXT | Stock# | Lot/UnitT | Wide | Length | Strenght |

| ALU | Flat Bags | Three-edge seal bags made of aluminum composite film | 10.013 | 48 St. | 920 | 1.750 | 100µ |

| MDPE | Flat Bags | natural transparent - without additives - S.welding - | 10.010 | 490 St. | 700 | 1.400 | 75µ |

| MDPE | Flat Bag with side g | red colored - with antistatic agent - without lubricant - withhot stamping - with 100 mm inserted side fold - with double bottom welding - | 10.015 | 4.700 St. | 550 | 690 | 100µ |

| MDPE | Flat Bag with side g | fluorescent orange dyed - with antistatic agent - without lubricant and slip - with hot stamping - with 150 mm inserted side fold - | 10.016 | 2.500 St. | 700 | 690 | 100µ |

| LDPE | Cover disk | Round foil blanks (lid discs) - diameter 240 mm - needled - | 10.018 | 4.300 St. | 280 | 280 | 100µ |

| LDPE | Flat Films/Foils tri | natural transparent - straight edges and neatly trimmed - without slip - 400 linear meters/roll - wound on a cardboard tube with a 76 mm core - | 10.019 | 310 Ro. | 50 | 0 | 70µ |

| LDPE | Flat Bags | natural transparent - with slip - 1 side, 1 color "BLUE" printed, bottom edge of print 30 mm above weld seam - | 77.739 | 9.875 St. | 180 | 410 | 100µ |

| LDPE | Flat Bags | natural transparent - with lubricant - S. welding - 1A product - | 10.012 | 7.500 St. | 235 | 280 | 180µ |

| LDPE | Flat Bags | Natural transparent - without slip - | 77.504 | 700 St. | 240 | 400 | 100µ |

| LDPE | Flat Bags | natural transparent - with antistatic agent - specific surface resistance less than or equal to 10 to the power of 11 square Ohm - | 77.093 | 150 St. | 1.000 | 1.600 | 90µ |

| LDPE | Flat Bags | natural transparent - without slip - S.welding - 50 pieces in a small box - | 74.882 | 300 St. | 1.000 | 1.800 | 80µ |

| LDPE | Folded Films on roll | Natural - with antistatic agent according to TRGS 727 - fire protection film - flame-retardant according to DIN 4102 - CAT B1 - 30 meters on the roll - cardboard tube 76 mm core | 76.001 | 1 Ro. | 3.600 | 0 | 160µ |

| LDPE | Folded Films on roll | natural transparent - 4000/2000 mm - 50 running meters per roll - wound on a core with a 76 mm cardboard core - roll weight approximately 28 kg - | 76.769 | 2 Ro. | 4.000 | 0 | 150µ |

| LDPE | Film Cuts | natural transparent - needled - | 10.017 | 35.400 St. | 280 | 280 | 100µ |

| LDPE | Tubes | Natural transparent - no additives - 150 linear meters/roll - wound on a cardboard tube with a 76 mm core - roll weight approximately 3 kg | 77.064 | 28 Ro. | 50 | 0 | 200µ |

| LDPE | Tubes | Natural transparent - with slip - 250 linear meters/roll - wound on a cardboard core with a 76 mm core - | 77.942 | 7 Ro. | 400 | 0 | 150µ |

| LDPE | Tubes | natural transparent - without lubricant - 100 meters on the roll - cardboard tube with roll core 76 mm - roll weight approx. 33 kg - | 1.346 | 1 Ro. | 1.750 | 0 | 100µ |

| LDPE | Box Hoods | Black, opaque, and UV stabilizer - Base dimensions 300 + 300 mm - assembled height 480 mm - in small boxes with inner bags - | 76.868 | 200 St. | 600 | 640 | 100µ |

| LDPE | Roundliner | natural transparent - with lubricant - diameter 320 mm - height 600 mm - | 76.509 | 1.750 St. | 515 | 630 | 50µ |

| LDPE | Flat Bag with side g | grey transparent coloured - with 240 mm inserted side fold - with S.welding - | 1.242 | 1.000 St. | 960 | 1.000 | 100µ |

| LDPE | Flat Bag with side g | blue transparent dyed - with 280 mm inserted side fold - With S.welding - | 1.239 | 890 St. | 1.140 | 1.200 | 100µ |

| LDPE | Flat Bag with side g | yellow transparent dyed - with 280 mm inserted side fold - With S.welding - | 1.240 | 1.080 St. | 1.140 | 1.200 | 100µ |

| LDPE | Flat Bag with side g | Natural transparent - with antistatic agent - with 275 mm inserted side fold - Specific surface resistance 10 to the power of 10 Square O | 76.784 | 550 St. | 1.300 | 1.000 | 90µ |

| LDPE | Flat Bags | Black opaque colored - conductive - surface resistance 10h6 square ohms - bundled in packs of 25 - with adhesive label "Warning" | 77.698 | 5.000 St. | 780 | 800 | 50µ |

| LDPE | Flat Bags | black colored - conductive - specific surface resistance less than or equal to 10 to the power of 7 square Ohm | 77.340 | 1.910 St. | 810 | 1.050 | 200µ |

| VFO | Flat Film/Tubes on r | Composite film inside black outside white - wound on rolls of 500 m - cardboard tubes with 76 mm core diameter - | 10.014 | 3 Ro. | 600 | 0 | 110µ |

Trade only with traders.

Polymer-Synthese-Werk GmbH

47495 Rheinberg/Germany

Manufacturer of bags, films and tubes made of LDPE, MDPE and PP.

Telephon: +49 2844 100

Fax : +49 2844 1015

Mail : info@polymersynthese.com